VARIVOLT is a variable transformer allowing to adjust voltage on load from 200 kVA to 30 MVA.

The voltage change takes place at the transformer's secondary (the primary is fixed).

The VARIVOLT is equipped with sliders that allow you to regulate voltage continuously and linearly, It can be seen as a transformer with an infinite number of sockets.

This transformer is optimised for installations requiring a variable power supply such as glass and metal furnaces and test platforms.

L’adaptation de la puissance en temps réel à la charge vous ensures optimum power consumption.

The VARIVOLT do not generate harmonics which could disrupt the electricity network and affect your electrical equipment.

De plus, les VARIVOLT n’intègre no DC component.

VARIVOLTs can be controlled remotely, which makes it possible for time saving and simplicité d’utilisation.

Avec un VARIVOLT, vous bénéficiez d’un facteur de puissance élevé, ce qui vous avoids the need to install a compensation system.

A VARIVOLT has a lifespan of over 40 years and on average requires low maintenance (every 400,000 pulses or about 10 years)

VARIVOLTs offer efficiency higher than 98 %, permettant ainsi de maximiser l’efficacité énergétique des systèmes en réduisant les coûts d’exploitation. Cela se traduit par des économies sur votre facture d’électricité.

The high and low voltage primary winding is produced in the conventional way. In addition, the primary and secondary windings are insulated, which makes it possible to have galvanic isolation.

Le bobinage secondaire est conçu à l’aide d’un profilé de cuivre rainuré. Il permet une évolution en charge et de façon continue de 0 à 100%.

VARIVOLT technology, with cursors in permanent contact with the copper and immersed in the oil, means that transformers can be made from 0 to 10 MVA

The primary voltage, fixed, is from 400V to 36.000V therefore it is adapted to all HV networks worldwide.

The secondary voltage is variable from 0 to 1.000V..

The maximum secondary current is about 10.000A.

The VARIVOLT secondary voltage is variable.

For example, with a distribution transformer, you have a voltage of 20,000V on the primary side and 400V on the secondary side.

With a VARIVOLT, you have 20,000V at the primary and a setting from 0 to 400V at the secondary.

Thus the varivolt allows the secondary voltage to be adjusted.

Thanks to the sliders that move along the windings, the VARIVOLT can be fine-tuned.

The number of turns selected on the secondary allows the voltage to be adjusted.

This electrotechnical principle does not interfere with the sinusoid and allows clean control.

The thyristor allows the sinusoid to be cut (phase angle regulation) or only a percentage of the voltage to pass (wave train regulation),

This power electronics technology generates harmonics on the network and causes shocks during voltage adjustments.

To sum up, a thyristor generates harmonics where a VARIVOLT does not.

Here is an example of an installation. In general, an installation consists of four elements:

BERNARD ENGINEERING control cabinets provide complete control of the Varivolt from the primary protection cell to secondary use. We offer 2 ranges of cabinets: with PLC (type MICVAR) or without PLC (type BB).

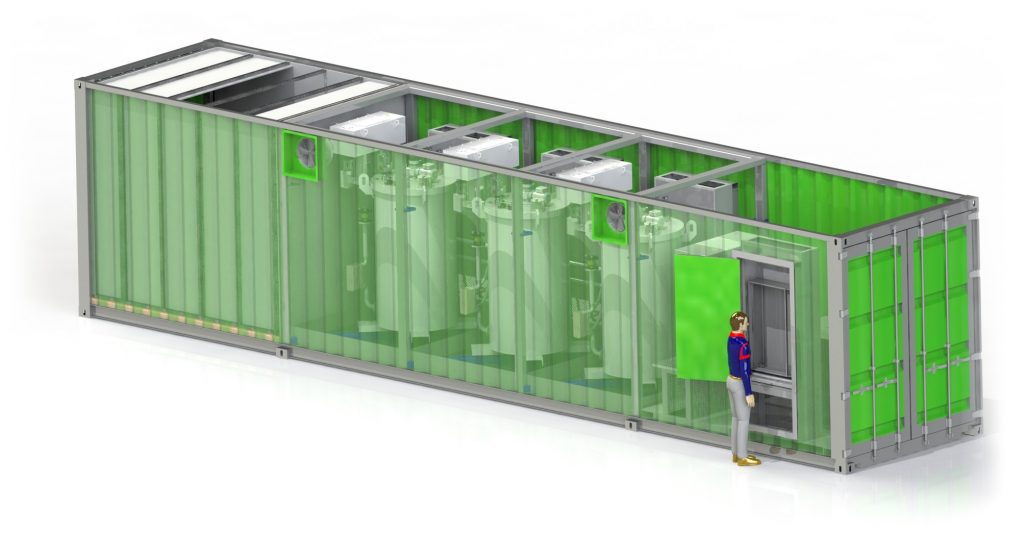

BERNARD ENGINEERING has developped a solution with VARIVOLT fixed in one container, 20’ or 40’ with primary protection and control command, in order to facilitate the installation, and allow the transport from site to site.

Application : Soil treatment, hydrogen production...

It includes the VARIVOLT, the primary protection cells, one or more auxiliary transformers, the control command, the retention tank. Just connect to the network and the application.

Bernard Engineering supplies engineering and services for variable electrical power systems AC or DC. Our expertise ranges from design to start-up assistance worldwide for glass, steel, electrochemical industry and platform of electrical tests.

Discover the expertise of our subsidiary Amppelec which designs made-to-measure electrical connections. In particular, we offer Bar Ducts .Opt for perfectly matched electrical connectivity with Amppelec.

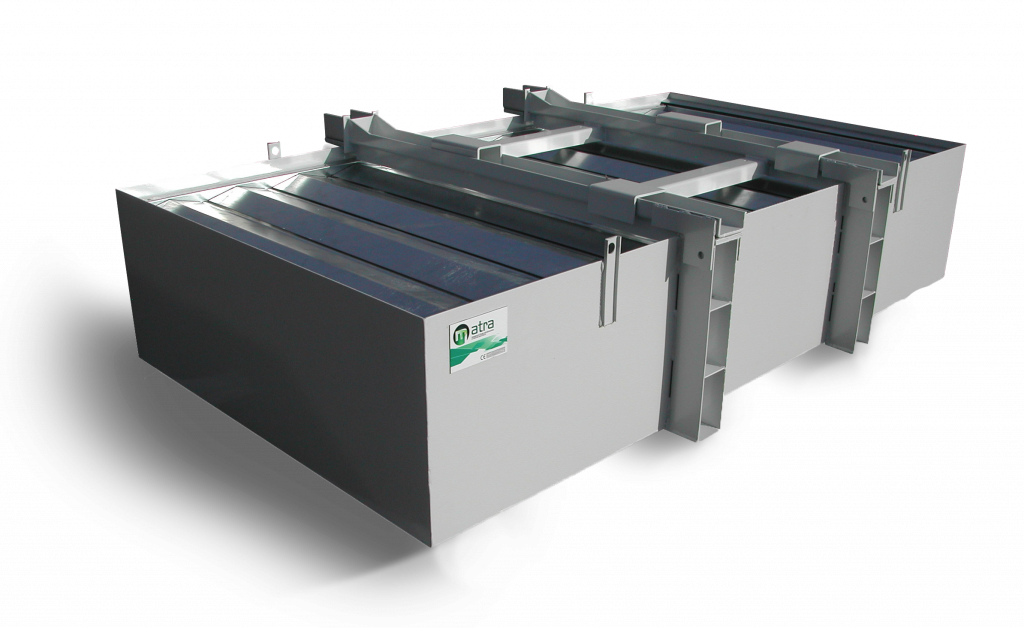

Discover our solution for optimum management of your VARIVOLTs. Our retention tanks are tailor-made to ensure unrivalled safety. They guarantee reliable protection that meets fire safety standards.

Our VARIVOLTs power the first all-electric oven of Verallia.

We contributed to the new Saint-Gobain flat glass production line on the Bhiwadi site in India.

Thanks to our Shelter installation, by offering a turnkey solution in a container, we made it easier and quicker to install the new furnace.

Our VARIVOLTs are used to power a slag remelting furnace.

This VARIVOLT has special features:

The functional part consists of a tank containing the step-down transformer and the VARIVOLT.

Siemens uses our VARIVOLTs for their test platform.

Thanks to the precise voltage control provided by our VARIVOLTs, it is possible to carry out a wide range of routine tests such as :

In 2022, John Cockerill has opted for our varivolt to power their electrolysers, jouant ainsi un rôle essentiel dans le processus de fabrication d’hydrogène.

This process of creating hydrogen using electrolyzers is based on using electricity to break down water (H₂O) into hydrogen (H₂) and oxygen (O₂).